Why PLC Automation Is the Backbone of Modern Bonding Machine Design

Why PLC Automation Is the Backbone of Modern Bonding Machine Design

A single batch failure in metallic powder bonding can cost manufacturers thousands of dollars in wasted raw materials and downtime. Why do some bonding processes achieve 99% consistency while others struggle with color separation?Industry data indicates that automation in powder coating can reduce batch defects by up to 30%, leading to higher consistency rates across production runs.

Leading companies in the field of powder coating gear, such as Yantai Jatchen Powder Coating Processing Equipment Co., Ltd., continue to advance limits. As a dedicated provider of equipment for powder coating production, Jatchen includes cutting-edge automation in their devices. This approach addresses the growing needs of manufacturing that focuses on high output and minimal waste. Their offerings go beyond simple devices. Instead, they represent clever setups designed for practical industrial settings.

What Is PLC Automation And Why Is It Critical For Bonding Machines?

Bonding machines handle complicated tasks. These include managing heat, blending movements, and careful handling of materials. A hands-on or partly automated method fails to provide the needed level of oversight and dependability for steady results. PLC automation fills this gap effectively.

Industrial PLC Control Systems

A PLC, which stands for Programmable Logic Controller, is a tough digital computer made for directing factory processes. In the creation of bonding machines, PLCs oversee main functions. For instance, they handle temperature increases, blending rates, lengths of time, and step-by-step operations. These devices endure rough factory environments. At the same time, they deliver quick responses in real time.

Intelligent Control System Features

Current bonding setups with smart controls include ready-made formulas, flexible adjustment options, and systems for managing alerts. Such elements cut down on differences and enable exact handling of process factors. The Bonding mixing machine uses PLC and HMI control. It operates with high levels of automation, multiple uses, and a tight build. This setup proves vital for keeping metal powder bonding steady.

PLC & HMI Integration Benefits

The Human-Machine Interface, or HMI, connects workers directly to the setup. Using screens or panel displays, users can watch current data, change settings, and pull up records of processes. With control systems that set details like speed, heat levels, and durations through touchscreens or computers, these combinations simplify fixing issues. They also make worker training easier and less demanding.

How Does PLC-Based Automation Improve Bonding Mixer Efficiency?

When it comes to efficiency in bonding mixers, the focus lies on processing materials fast and evenly. At the same time, it involves cutting back on stoppages. Systems controlled by PLC reach these aims through automation. This removes uncertainty and unevenness from the equation.

Automated Mixing And Crushing

Automation lets mixers run planned cycles for warming, cutting, blending, and chilling. All this happens without any hands-on input. As a result, there are no pauses between phases. Each group of materials gets handled in the exact same way. Fast-moving blades create strong flows and cuts. This guarantees complete blending and solid sticking of bits. Such results depend on closely supervised automated steps.

High Consistency In Material Composition

The standard of bonded powder hinges on even spread of metal colors with resin bits. Control through automation over heat and schedules helps avoid too little or too much handling. Consequently, this leads to stronger spread of colors and improved looks in decoration.

According to industry benchmarks for metallic powder coating, manual temperature fluctuation should be kept within ±1°C to prevent color shift. Jatchen’s PLC system achieves this by using PID control loops, ensuring the Delta E (color difference) remains below 0.5 across different batches.

Reduced Human Error And Safety Enhancements

Automation takes over regular jobs and adds lockout features. In this way, it greatly lowers the chance of worker slip-ups. Several protections exist. For example, overload guards halt extra strain. Door locks block entry to active sections while running. These show clearly how automation boosts safety in the work area.

Why Should Industrial Bonding Equipment Incorporate PLC Control?

More than just short-term efficiency boosts, adding PLC control to bonding gear brings lasting gains in daily operations. These advantages lift the whole production flow to a higher level.

Real-Time Process Monitoring

Live views of details such as inside heat, engine strain, and run times allow for fast action if problems arise. This prevents failed groups and lost materials.

Programmable Operation And Error Prevention

Workers can save various formulas inside the setup. This speeds up shifts between product kinds. On top of that, fault signals and checks give rapid input to repair groups. As a result, there is less idle time and more active periods.

Energy Efficiency And Maintenance Optimization

Setups with automation can run engines only during necessary moments. They can also shift to low-power states when not in use. This cuts energy use while keeping output steady. Industry benchmarks from 2024 indicate that automated powder coating systems can achieve energy savings through smart controls, with some setups reclaiming over 95% of unused powder and minimizing idle times.In addition, upkeep that looks ahead becomes feasible. It uses info from detectors sent to a main hub.

How Does PLC Automation Optimize Powder Coating Bonding Machines?

Powder coating demands that bonding machines offer not only exactness but also the ability to adjust to various mixes and bit sizes.

Precise Temperature And Speed Control

Resin bonding depends on managed warming that avoids harm to parts. Systems with fine accuracy adjust bonding heat levels. They make sure only slight melting happens for the best sticking. This prevents bits from merging or colors from shifting undesirably.

Particle Size Optimization System Integration

Jatchen provides a special particle size optimization system. The company developed this on its own. When combined with a PLC, it allows changes on the fly. These adjustments rely on instant input from detectors that track material traits.

Enhanced Powder Flowability And Adhesion

Automation of cut strength and blending lengths through smart coding improves the flow of the final powder. Strong flow proves crucial for how it works in actual use.

Which Jatchen Bonding Machines Highlight PLC Advantages?

The gains from PLC automation go beyond ideas at Jatchen. They appear in every unit sent out globally. Several top models stand out in this regard:

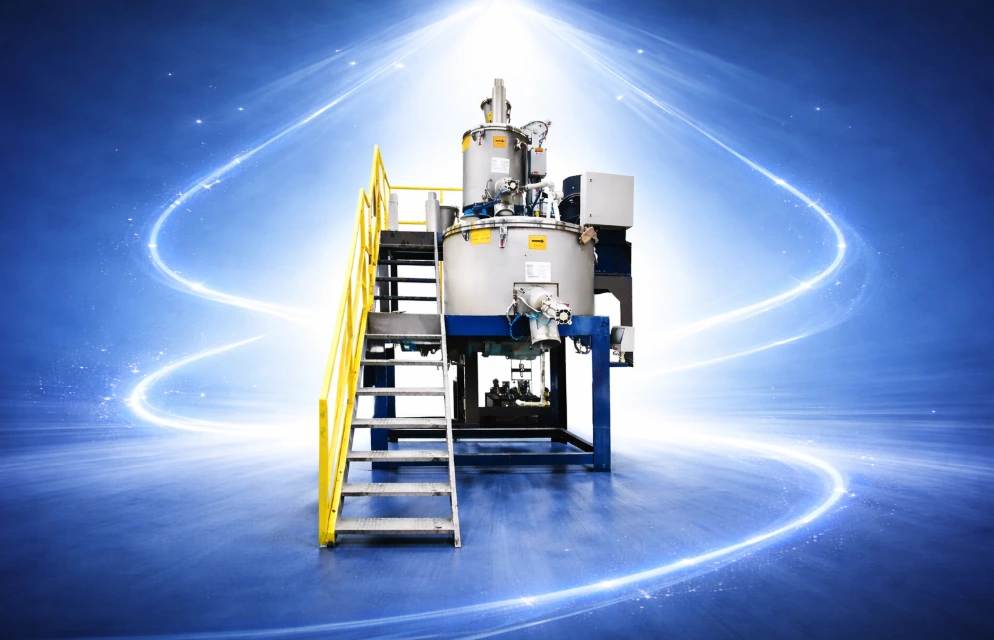

BD Series Bonding Mixer With PLC&HMI

This main item shows automation through easy-to-use displays and flexible control setups. The Bonding mixing machine supports effective bonding. It relies on powerful stirring, cutting, and managed heat phases.

CM Series Automatic Container Mixer

This version raises adaptability further. The entire procedure runs under PLC and HMI guidance. It blends evenly and achieves strong output. Such a design fits well for plants of medium to large size. These operations need easy shifts between groups without losing quality.

High-Speed Mixers HLJ Series

Not all tasks call for gentle treatment. Some demand heavy action. Jatchen’s HLJ series works for breaking and blending solid, rough, and clumped multi-part materials. All this occurs while holding firm process oversight via its PLC foundation.

How Can PLC-Based Automation Support Lean Production Lines?

Lean manufacturing succeeds through less waste, quicker switches, and stronger tracking. Intelligent automation makes all these possible.

Multi-Batch Production And Flexibility

Automation helps sites change between product sorts rapidly. It does this by loading ready programs into the guide. No need for fresh tuning occurs. This adaptability aids in handling smaller groups. At the same time, it preserves overall flow.

Centralized Control And Data Storage

Be it one mixer or a full line, central PLC setups enable matched oversight and record-keeping across devices. This aids in reports for rules and tracking of groups.

Quick Cleaning And Color Change Efficiency

Options like removable blades and even inner walls make cleaning straightforward. Parts that come off allow deep washes. This cuts risks of mixing between groups. Such steps matter greatly when handling various colors or mixes one after another.

What Future Benefits Can Manufacturers Expect From PLC-Integrated Bonding Machines?

As the sector heads toward digital shifts, those who adopt automated bonding tech early already notice big returns over time.

Improved Product Consistency And Quality

Automation cuts out changes linked to hands-on work. Uniformity from group to group rises a lot. This happens because each phase runs under watched conditions with saved programs.

Lower Labor Costs And Increased Automation

With fewer hands-on duties per group, trained staff can move to tasks of greater worth. Examples include checking quality or research work. In the long run, this brings down costs of running per item made.

Scalable Production And Industry 4.0 Readiness

Today’s setups plan for growth ahead. Whether adding room or linking with planning software, machines based on PLC work well with Industry 4.0 structures. This places your site ready for smart factory changes.

To check out smart bonding tech suited to your setup, look at Jatchen’s product center. Or, review their complete automation range through the solution center and case studies. For help or unique needs, reach out via their official contact page.

FAQ

Q1: How does PLC automation enhance safety in bonding machines?

A: By adding overload protection, door interlocks, and auto-stop functions into the main logic, PLCs cut risks a great deal during use.

Q2: Can a bonding mixer handle different types of powder formulations automatically?

A: Yes. Formulas kept in the PLC let the device adjust details like blending rates and warming times for varied material setups. No hands-on changes are needed.

Q3: What maintenance advantages does a PLC-controlled system offer?

A: Live checks and forward warnings help spot problems early. This keeps stoppages low and stretches the life of gear.

Q4: Is it possible to scale up production using the same PLC platform?

A: Absolutely. Current PLCs allow add-on growth in modules. Adding units or better functions becomes simple as needs increase.