Top Twin Screw Extruder Manufacturers

Top Twin Screw Extruder Manufacturers

The global twin screw extruder market is a cornerstone of modern industrial manufacturing, underpinning advanced production in plastics, polymers and specialty coatings. According to recent industry research, the total market for twin screw extruders was valued at nearly USD 3.0 billion in 2024 and is projected to grow to over USD 4.7 billion by 2033, expanding at a compound annual growth rate (CAGR) of approximately 5.3 % between 2025 and 2033.

This steady expansion reflects the increasing demand for high-performance processing equipment capable of delivering consistent quality, precise material blending, and robust operational efficiency for continuous production environments. In particular, co-rotating twin screw designs have captured more than 70 % of global market share due to their superior mixing, self-cleaning characteristics, and adaptability across complex formulations.

In the context of powder coating manufacturing, where homogenous dispersion, thermal stability, and reproducible melt characteristics directly influence downstream cooling, grinding, and classification, twin screw extruders play a decisive role in defining final product quality. Establishing a comprehensive view of extrusion as part of an integrated production chain thus becomes essential for industrial users aiming for long-term consistency and minimized waste.

What Makes a Twin Screw Extruder Manufacturer Trustworthy?

In powder coating tasks for factories, twin screw extruders need to function well past basic short-run aims. They have to back ongoing output plans. In addition, they must handle common recipe shifts. Furthermore, they should keep steady amid changing workload levels. This avoids problems in following steps. Over years, work logs always point out that ongoing mechanical firmness and reliable actions weigh much more than top volume stats. So, builders with true site know-how pay attention to useful design markers. These include torque evenness over work spans. They also involve screw damage buildup as time goes on. Plus, setups that make tweaks and regular care simpler count as key factors.

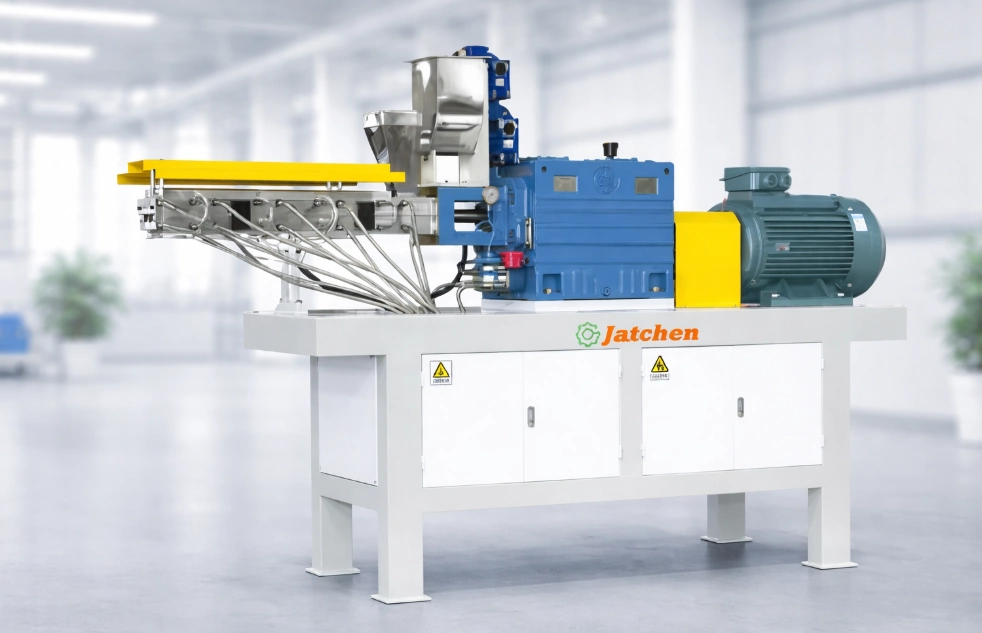

Yantai Jatchen Powder Coating Processing Equipment Co., Ltd. stands out with this very output-focused outlook. It does not treat twin screw extruders as standalone units. Instead, Jatchen crafts them as vital pieces in full powder coating production setups. This broad-system method mirrors the company’s steady expertise in powder coating handling tools. It includes blending, extrusion, cooling, breaking, milling, and size handling. Through building extrusion sections to align with earlier material readying and later cooling and grinding parts, Jatchen guarantees that extrusion results stay firm in actual plant surroundings. This holds true beyond lab trials or quick test cases.

Using years of field startup and steady upgrade work, Jatchen blends real know-how straight into its twin screw extruder plans. These cover careful torque buffers for lasting use. Screw and barrel arrangements get picked to cut down lopsided damage. Plus, worker-easy builds aid regular color swaps and recipe tweaks. These plan picks show a strong sense of how powder coating sites run each day. In those places, dependability, simple management, and step steadiness finally set output amounts and running fees.

Why Does Twin Screw Extrusion Matter in Powder Coating Production?

Twin screw extrusion goes beyond a basic blending phase. It establishes the pattern for all subsequent steps. When blending proves uneven here, the following cooling, breaking, and milling phases can fix only a limited amount.

In everyday plants, workers spot troubles first via small indicators. These include torque variations, uneven sheet depth on the cooling strip, or elevated mill pressure. Such signs seldom occur by chance. They usually link back to extrusion actions.

Jatchen’s design insights point out that co-rotating twin screw extruders, if set up correctly, deliver steadier melt movement and superior material blending for powder coating manufacturing chains. This steadiness aids in maintaining particle size spread inside desired limits during later stages. As a result, it cuts down on reprocessing and scrap.

You can observe the role of extrusion in overall system planning via Jatchen’s solution center. There, extrusion receives treatment as an integrated element.

How Does Yantai Jatchen Design Twin Screw Extruders for Industrial Use?

In working environments, twin screw extruders have to behave in a foreseeable manner. They must allow simple tweaks. Also, they should tolerate shifts in manufacturing conditions without major issues.

Technical Specifications: Jatchen TSK Series Twin Screw Extruders

| Model | Output (kg/h) | Screw Diameter (mm) | Screw Speed (rpm) | Main Motor (kW) | Heating/Cooling Zones | Application Segment |

|---|---|---|---|---|---|---|

| TSK22 | 2 – 5 | 22 | 600 | 2.2 4 | 2 / 1 5 | R&D / Lab Testing |

| TSK30 | 10 – 15 | 30 | 600 | 4 | 2 / 1 | Pilot Line / Sampling |

| TSK35 | 50 – 80 | 35 | 600 | 7.5 | 2 / 1 | Small Batch Production |

| TSK40 | 150 – 200 | 40 | 600 | 18.5 | 2 / 1 | Medium Batch Line |

| TSK55 | 300 – 500 | 55 | 500 | 30 | 2 / 1 | Standard Industrial Line |

| TSK65 | 600 – 800 | 65 | 420 | 45 | 2 / 1 | High Output Industrial Line |

| TSK75 | 800 – 1000 | 75 | 420 | 55 / 75 | 2 / 1 | Large Scale Manufacturing |

| TSK85 | 1000 – 1200 | 85 | 420 | 90 / 110 | 2 / 1 | Heavy-Duty Mass Production 48 |

| TSK98 | 1200 – 1500 | 98 | 420 | 110 / 135 | 2 / 1 | Ultra-High Capacity Plant |

Engineering Logic Behind the Structure

Prior to covering models or details, consider the reasoning in Jatchen’s twin screw extruder build. The screw and barrel setup prioritizes reliable transport and uniform blending. Gearboxes get chosen for extended service periods. Multi-zone heat management tracks actual material responses seen in operating lines.

Such a method stems from experiences in prolonged powder coating operations. Many of these appear in Jatchen’s case center.

Twin Screw Extruder Product Configuration

Among Jatchen’s lineup of gear, the TWIN SCREW EXTRUDER gets built to blend seamlessly into full powder coating lines. Screw sizes, length-to-diameter ratios, and input mechanisms get picked according to scale of output and recipe demands.

Instead of imposing fixed designs, Jatchen tailors screw parts and input methods to fit your production aims and space setup. This adaptability lowers extra complications at setup and routine use.

How Does Integration Improve Production Stability?

A twin screw extruder seldom breaks down by itself. Issues typically arise from weak links with prior or following machines. Therefore, smooth integration holds great importance.

Role of Extrusion in the Full Line

Within a whole powder coating manufacturing chain, extrusion connects initial material prep with forming and size cutting. If extrusion yield varies, the cooling strip faces challenges. When input lacks consistency, the breaker and mill endure extra strain.

Jatchen’s overall layout views extrusion as a key adjustment spot rather than a mere handover phase. Settings at the extruder aim to sync with the pace of cooling, breaking, and milling tools provided in the same package.

What About Control, Operation, and Daily Use?

Sophisticated control setups benefit operators only if they simplify everyday tasks. In actual plants, staff prefer straightforward reports and basic changes, not complex screen layers.

Jatchen twin screw extruders employ PLC-driven control units that target essential factors like torque, rotation rate, and heat sections. The aim stays practical: to spot issues soon. Thus, when shifts occur, they become clear before impacting output standards.

How Reliable Is Long-Term Operation?

True dependability emerges after countless running hours. Patterns of wear, seal durability, and gearbox response outweigh easy initial starts.

From Jatchen’s upkeep logs, steady extrusion results over periods rely on even mechanical builds and sensible service timings. Parts get picked to minimize surprise halts. Upkeep entry points form part of the initial design, not later additions.

If upkeep becomes necessary, organized aid via the service center allows planned fixes over crisis responses.

Why Choose Yantai Jatchen as Your Twin Screw Extruder Partner?

When picking a twin screw extruder maker for industrial powder coating output, the core issue boils down to one point. Does this provider grasp how your setup functions on an ordinary day, beyond just the setup phase?

Drawing on years of work in powder coating gear, Yantai Jatchen Powder Coating Processing Equipment Co., Ltd. prioritizes reliable yield, workable oversight, and enduring support benefits. Its extrusion setups form pieces of complete manufacturing chains, guided by practical site comments over abstract ideas.

For in-depth talks on tech, space planning, or output boosts, reaching out directly through the contact page usually yields sharper responses than broad price offers.

FAQ

Q1: How do you know if a twin screw extruder fits your powder coating production scale?

A: Assess your ongoing output requirements, work shift routines, and capacity in later phases. A well-suited extruder operates in harmony with cooling and milling steps. It avoids overloading them.

Q2: Why is integration more important than individual machine performance?

A: Extrusion influences each subsequent process. When settings at extrusion match the entire chain, standards remain consistent. Operators then devote less effort to fixing errors.

Q3: How often does a twin screw extruder require maintenance in industrial use?

A: Service periods vary with runtime hours and recipe alterations. Strong builds stress regular check times over urgent fixes.

Q4: What support matters most after installation?

A: Straightforward tech exchanges, parts supply strategies, and procedure advice hold the highest value.