Grinding Mill Particle Size Control: How to Achieve Stable D50 and D90 in Powder Coating

Grinding Mill Particle Size Control: How to Achieve Stable D50 and D90 in Powder Coating

Particle size control sits at the center of powder coating performance. You can reach a target once, but holding that target day after day is what decides surface quality, transfer efficiency, and production stability. Many plants discover this only after output increases and small variations begin to show up as uneven coating or rework. This article focuses on grinding mill particle size control in real production conditions, with special attention to stable D50 and D90 results.

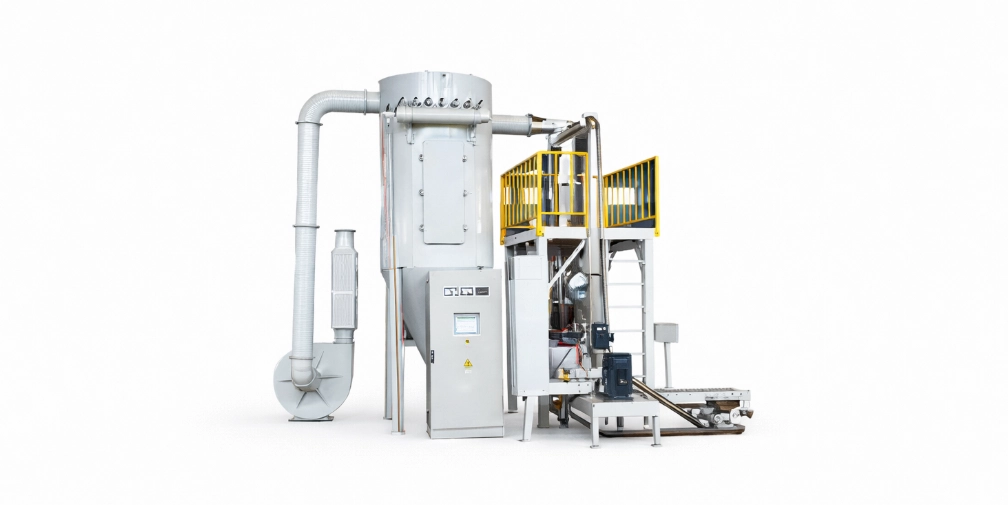

When discussing practical solutions in this field, Yantai Jatchen Powder Coating Processing Equipment Co., Ltd. often comes up in technical conversations. The company has spent years building powder coating grinding mill systems around production consistency rather than short test runs. Through its product portfolio, solution center, case studies, and service support, Jatchen focuses on grinding mill fineness control and long-term particle size stability for industrial powder coating lines.

Why Is Grinding Mill Particle Size Control More Important Than Output Capacity?

In many factories, output capacity is easy to measure. Particle size stability is harder to see, yet it defines whether your powder coating grinding mill truly works for your line.

Particle Size Stability As The Real Measure Of Grinding Mill Performance

A grinding mill particle size control system is judged by how stable the result stays. You may hit a grinding mill target particle size during setup, but if D50 and D90 drift after several hours, coating results will follow. Consistent particle size grinding mill performance means fewer spray adjustments and less scrap. Many production teams accept small variations at first, only to find that batch-to-batch powder grinding mill consistency becomes a hidden cost.

The Relationship Between Grinding Mill Fineness Control And Coating Uniformity

Grinding mill fineness control links directly to powder coating particle size uniformity. Narrow particle size distribution supports even film build and predictable flow during spraying. When fineness fluctuates, some particles melt and flow faster while others lag behind, creating surface inconsistency.

Why Powder Coating Grinding Mill Selection Starts With Target Particle Size

Choosing a grinding mill for powder coating should begin with the required D50 and D90, not with motor size or maximum output. Grinding mill D50 control and grinding mill D90 control define how well the mill fits your formulation and application method. Output capacity only adds value when particle size stays within range.

How Can A Grinding Mill Achieve Stable D50 And D90 Over Long-Term Operation?

Reaching stable D50 D90 powder grinding mill results requires structural design and operating logic that support consistency over time.

Once production runs extend beyond short tests, long-term behavior becomes visible.

D50 And D90 Control Through Optimized Grinding Structure

Stable grinding mill D50 D90 performance depends on how material moves through the grinding and classification zones. Systems designed for steady airflow and controlled impact help hold D50 and D90 values without constant manual correction. This approach supports powder coating D50 particle size targets even as feed rates change.

Consistent Particle Size Grinding Mill Performance In Continuous Production

In continuous operation, grinding mill particle size variation often appears gradually. Consistent particle size grinding mill systems reduce that risk by keeping internal conditions balanced. Over time, this supports grinding mill long-term particle consistency and reduces requalification work between shifts.

Maintaining Grinding Mill Particle Size Stability During Extended Runtime

Grinding mill size drift over time usually results from small imbalances adding up. Monitoring fineness trends and maintaining steady feed conditions help prevent that drift. Plants that track grinding mill particle size stability across full production days tend to see fewer surprises.

What Causes Grinding Mill Particle Size Distribution To Become Uneven?

Grinding mill particle size distribution problems usually follow a pattern that can be traced back to process behavior.

Internal Airflow And Classification Influence On Particle Size Distribution

Grinding mill particle size distribution control relies heavily on internal airflow. When classification becomes unstable, coarse particles stay too long while fine particles circulate repeatedly. This widens the distribution and breaks powder coating particle size uniformity.

Over Grinding And Fine Powder Accumulation Inside The Mill

A common grinding mill over grinding problem appears when fine material remains inside the system longer than needed. This grinding mill fine powder issue shifts D90 downward while creating excess fines. Over time, that imbalance increases particle size variation.

Coarse Particle Retention And Incomplete Size Reduction

On the opposite side, grinding mill coarse particles problem occurs when material exits before full size reduction. This creates grinding mill uneven particle size and visible coating defects.

How Do ICM And ACM Grinding Systems Support Narrow Particle Size Distribution?

ICM Grinding System Design For Narrow Particle Size Distribution Control

The ICM GRINDING SYSTEM is structured to support narrow particle size distribution grinding mill requirements. Its integrated grinding and classification approach helps maintain steady particle flow, which supports grinding mill particle size distribution control across varying loads.

ACM Grinding System Configuration For Precise D50 And D90 Adjustment

The ACM GRINDING SYSTEM focuses on precise adjustment points that allow how to control D90 in grinding mill operation. By tuning airflow and classification speed, operators can fine-tune grinding mill D90 control without disturbing D50 stability.

System-Level Particle Size Consistency Across Different Production Loads

Both systems support maintaining consistent fineness in grinding mill operation by keeping classification behavior predictable. This system-level approach helps maintain powder grinding mill consistency when production demand changes during the day.

How Can Grinding Mill Particle Size Remain Consistent With Different Powder Formulations?

Different formulations introduce new challenges to particle size control.Even small changes in composition can affect grinding behavior.

Grinding Mill Adaptability To Resin And Pigment Ratio Changes

Learning how to control particle size in grinding mill systems starts with adaptability. Changes in resin to pigment ratio affect breakage behavior. Equipment that allows stable airflow and controlled residence time handles these shifts with fewer adjustments.

Particle Size Distribution Stability Across Multiple Powder Recipes

Grinding mill particle size distribution stability across different recipes depends on classification efficiency. When classification responds quickly, the system avoids wide swings and supports grinding mill particle size stability.

Maintaining Target Particle Size Without Frequent Parameter Adjustment

Frequent adjustments often signal weak system design. A grinding mill target particle size should remain stable through minor recipe changes. This reduces operator workload and keeps production smooth.

What Practical Methods Help Maintain Grinding Mill Particle Size Stability?

Beyond equipment choice, daily operation habits make a measurable difference.Small actions often separate stable systems from unstable ones.

Operational Parameter Control For Consistent Grinding Results

Steady feed rate and airflow help maintain consistent fineness in grinding mill processes. Sudden changes increase grinding mill particle size variation and push the system outside its stable zone.

Process Monitoring To Prevent Particle Size Drift Over Time

Tracking trends rather than single measurements helps detect grinding mill size drift over time early. Many plants only react after coating quality drops, which is already too late.

Equipment Selection Based On Long-Term Particle Size Performance

Selecting equipment with proven grinding mill long-term particle consistency reduces trial-and-error later.

Why Integrated Grinding Mill Solutions Improve Powder Coating Consistency?

Grinding Mill Integration With Powder Coating Production Lines

A grinding mill for powder coating performs best when integrated with upstream and downstream processes. Stable feeding and controlled discharge support powder coating particle size uniformity across the line.

System-Level Control For Particle Size Uniformity

System-level control keeps powder coating D50 particle size consistent from batch to batch. This reduces the need for spray line corrections and improves overall efficiency.

Technical Support And Process Optimization From Jatchen

Access to solution guidance, service support, and documented cases helps plants avoid common mistakes. Through its solution center, case references, service resources, and direct contact channels, Yantai Jatchen Powder Coating Processing Equipment Co., Ltd. supports grinding mill particle size control beyond equipment delivery.

FAQ

Q1: Why does grinding mill particle size change after several hours of operation?

A: Grinding mill particle size variation often comes from airflow imbalance, classification wear, or feed instability. Over time, these factors cause grinding mill size drift over time if not monitored.

Q2: How can you control D90 in grinding mill operation more precisely?

A: How to control D90 in grinding mill processes depends on classification speed and airflow balance. Fine adjustment in these areas improves grinding mill D90 control without affecting D50 too much.

Q3: What causes a grinding mill fine powder issue?

A: A grinding mill fine powder issue usually results from over grinding or excessive circulation of already fine particles. This often appears together with a grinding mill over grinding problem.

Q4: Why do coarse particles appear even when average size looks correct?

A: Grinding mill coarse particles problem can exist even when D50 looks acceptable. Uneven classification leads to grinding mill uneven particle size and poor coating appearance.

Q5: How do you maintain powder grinding mill consistency across different batches?

A: Powder grinding mill consistency improves when equipment design supports stable classification and when operating conditions remain steady. Long-term monitoring helps maintain grinding mill particle size stability across batches.