•High mixing efficiency: Equipped with high-speed stirring blades, it generates strong shearing and centrifugal forces, enabling full mixing in a short time. Typically, a batch can be uniformly mixed in 3-5 minutes, which is several times more efficient than ordinary mixers, greatly shortening production cycles and boosting efficiency.

•Excellent mixing uniformity: Unique stirring structure creates complex 3D circular flow of materials. Both materials with large density differences and different particle sizes can be fully stirred in all directions, achieving high uniformity. This ensures consistent color and performance during powder coating spraying, avoiding issues like color difference and uneven coating performance.

•Wide material adaptability: Suitable for various powder coating materials. For easily agglomerated pigments, high-speed stirring’s strong shearing can effectively break up agglomerates. For different formula systems (e.g., epoxy, polyester), ideal mixing effects can be achieved by adjusting stirring speed and time.

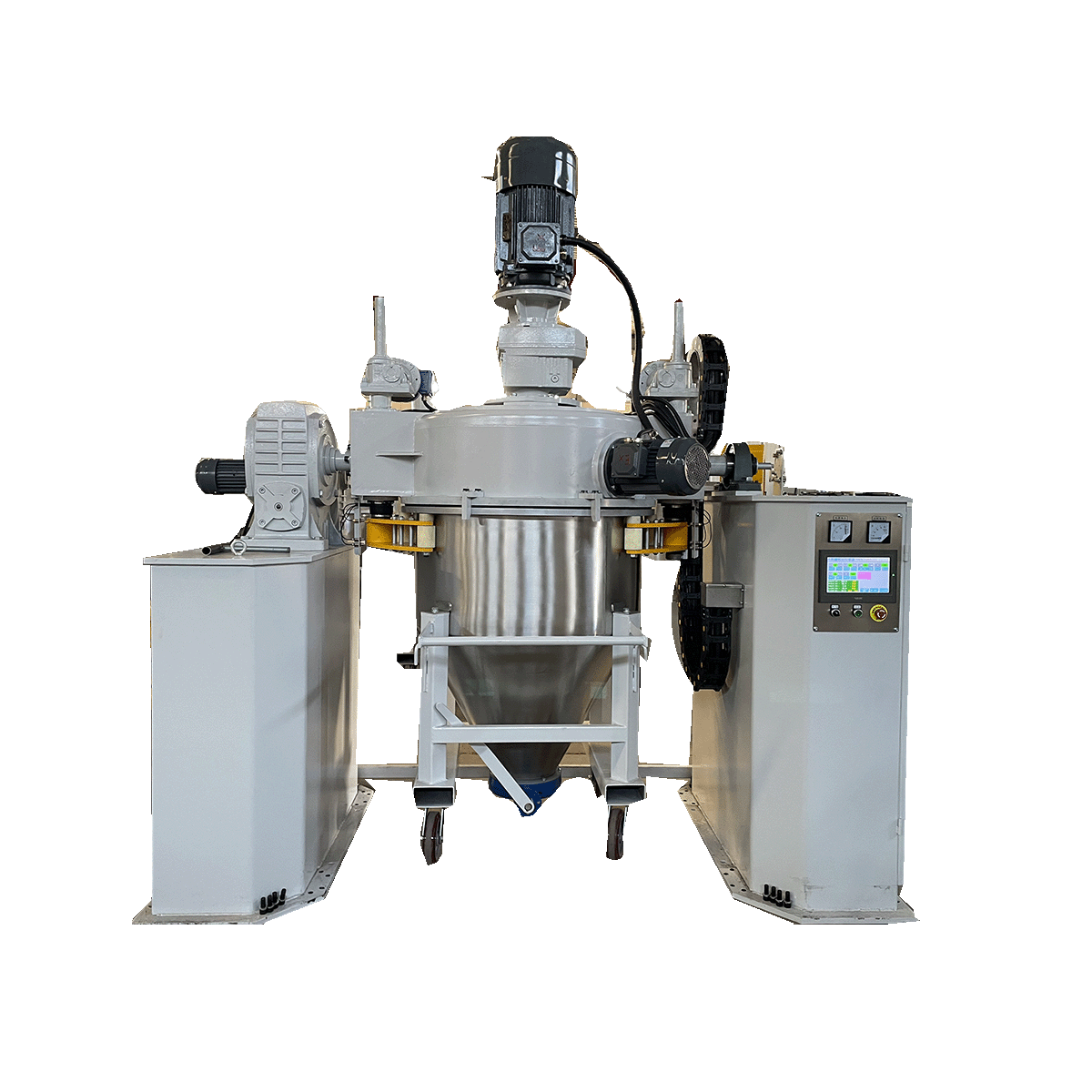

•Easy and flexible operation: Equipped with an intuitive interface, allowing operators to easily set parameters (stirring speed, time) and start/stop with one key. It can also flexibly adjust batch volume according to needs, suitable for both small-batch lab R&D and large-scale industrial production.

•Easy cleaning and maintenance: Material-contacting parts (stirring blades, mixing cylinder body) are made of stainless steel, featuring corrosion resistance and no material adsorption. Some parts are detachable for thorough cleaning between batches, preventing cross-contamination and ensuring product quality. Key parts have good wear resistance and long maintenance cycles, reducing costs.

•Reliable safety: Equipped with complete safeguards, such as overload protection (automatically cutting off power to prevent motor burnout when overloaded) and lid-open shutdown protection (immediately stopping when the protective cover is opened, avoiding operator risks).