Mixer – AUTOMATIC CONTAINER MIXER | Jatchen

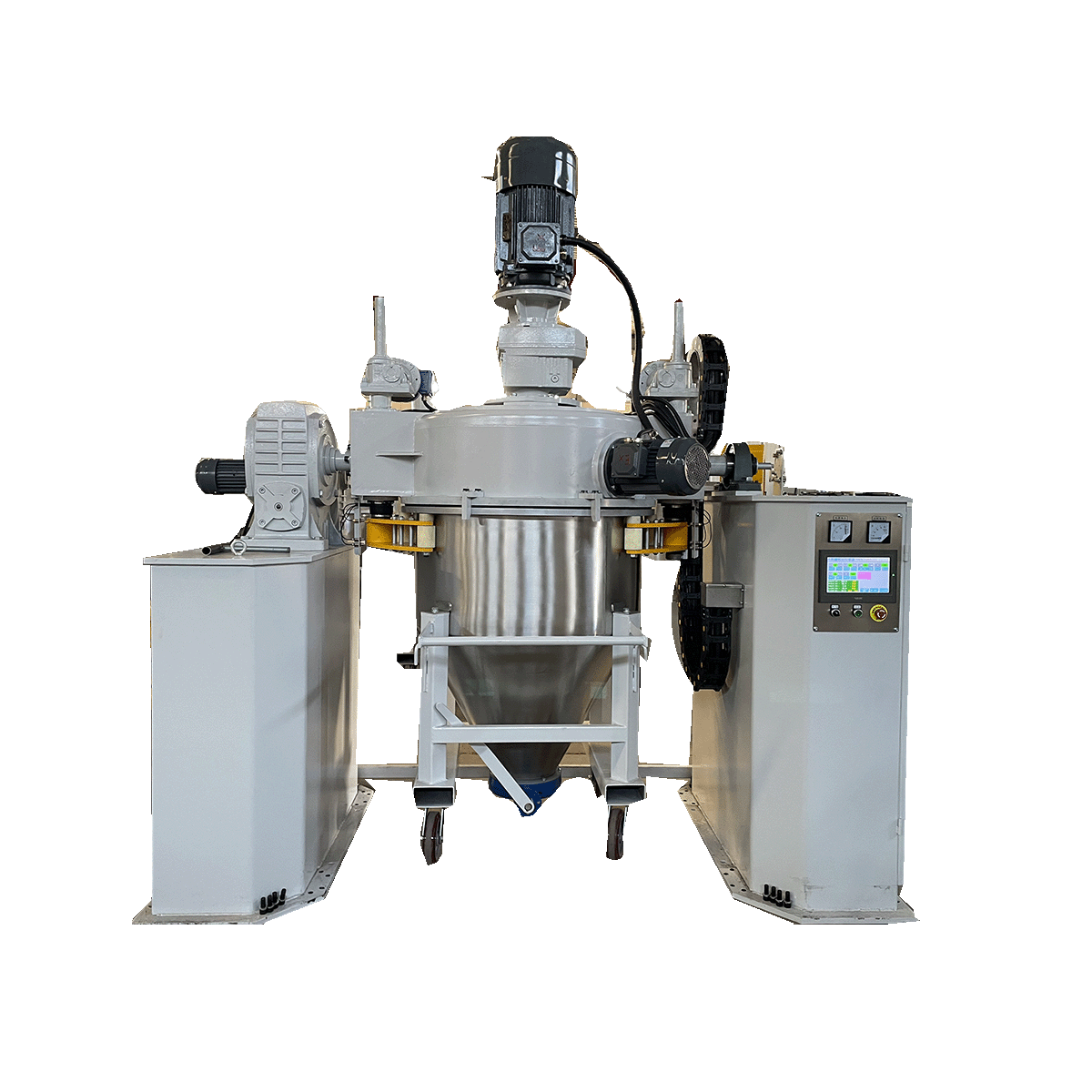

Automatic container mixer mainly consists of mixing container, flipping drive, stirring parts, frame and control system. During operation, raw materials like resins, curing agents, pigments, fillers and additives are added into the container in formula ratio. Then, the flipping drive rotates the container, while stirring parts spin at high speed inside, stirring, shearing and tossing materials. Under dual actions of flipping and stirring, materials constantly change positions and motion states, achieving full mixing and uniform dispersion. After mixing, the material is discharged through the outlet for subsequent processes like extrusion and bonding.