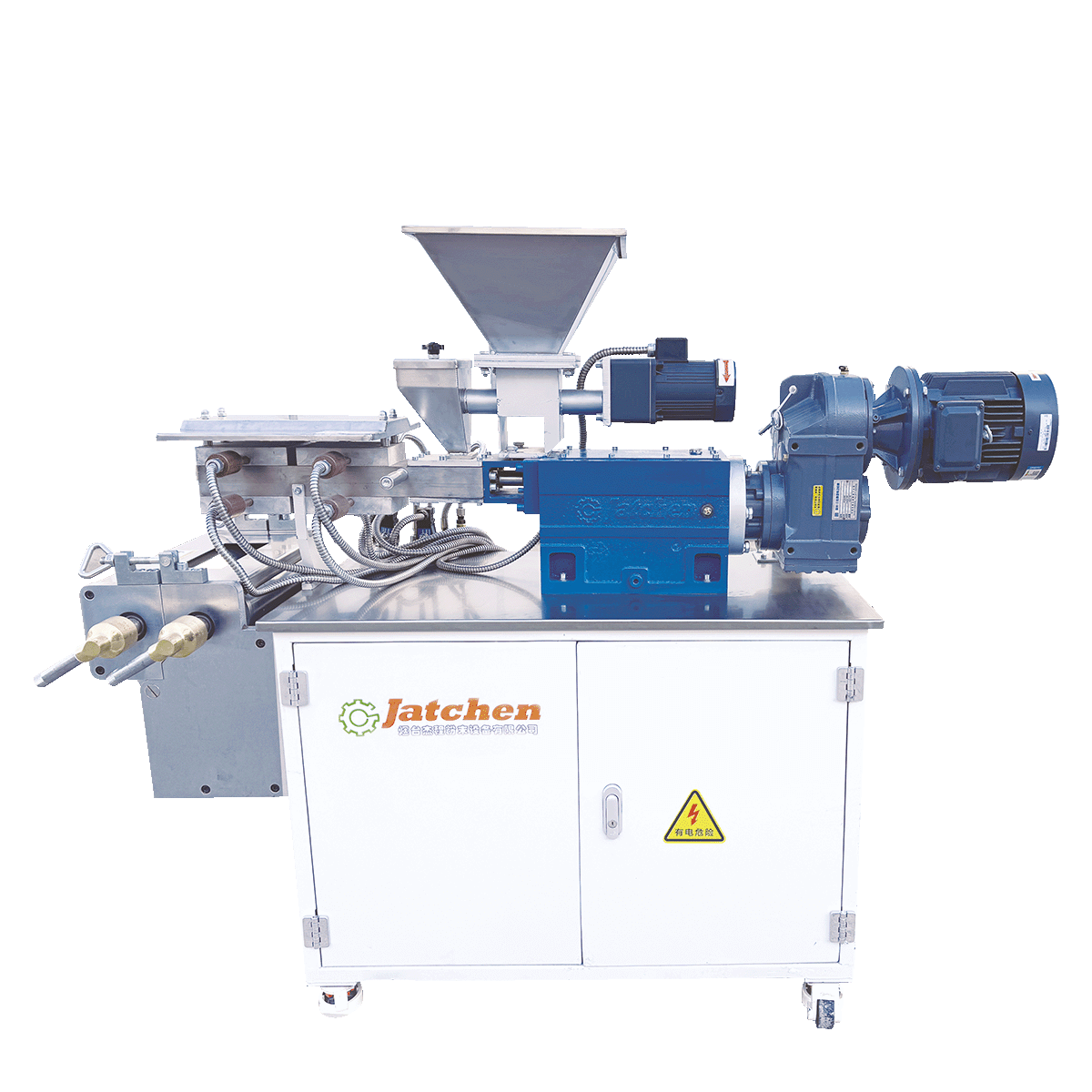

Laboratory Equipment – LAB EXTRUDER WITH ROLLERS | Jatchen

Lab extruder with rollers is used to melt, extrude, knead premixed powder coating raw materials, and press the extrudate into sheets via its roller unit. Its workflow: uniformly mixed materials are fed into the extruder barrel via a hopper, moved toward the die by a rotating screw, heated to molten state by external heaters, and further dispersed evenly under the screw’s shearing and kneading. The molten material is then extruded into the roller unit, pressed into sheets of specific thickness and shape for subsequent crushing, sieving, and final powder coating production.